CM Belt Drive Utility Vent Set

Utility Vent Sets

Model Features

- Performance: 500-25,000 CFM with Static Pressures up to 5-1/2" w.g.

- Backward inclined CW or CCW orientation non-overloading wheels, sizes 10 to 36"

- Steel sheet metal construction with corrosion resistant Epoxy Powder Coating, and welded scroll for airtight lock seam

- Miami-Dade NOA and Florida Product Approval Option Available Download letter here.

- Adjustable rotation and discharge orientations in accordance with AMCA 99-2406-83 Standards

- AMCA Air and Sound Licensed (except size 10)

Model CM

- cULus 705, Power Ventilator

- Operating Temp -20°F to +200°F continuous

Model CM-RHUL

- cULus 762, Power Ventilator for Restaurant Exhaust Applications

- Operating Temp -20°F to +400°F continuous

Model CM-HT

- cULus 793, Power Ventilator for Smoke Control Systems

- Designed and UL Listed to withstand inlet temperatures of 500°F for 4 hours and 1000°F for 45 minutes.

Models CM with AMCA-C Assembly Kit (option)

- cULus705, Power Ventilator

- Operating Temp -20°F to +200°F continuous.

- AMCA TYPE-C Spark Proof Rating

- Corrosion resistant epoxy coated steel wheel and scroll with non-ferrous inlet venture

Model Overview

The CM Series belt driven backward inclined Utility Vent Set fans to offer an excellent choice for all medium and high-pressure exhaust or supply applications for commercial, institutional or light industrial air movement projects. All models are supplied complete with the motor mounted on an adjustable base, v-belt drives, heavy-duty ball bearings and integral mounting platform. The installer-friendly design simplifies and reduces the cost of installation. Each complete fan is tested prior to shipping to ensure smooth, vibration free and consistently reliable operation to provide years of dependable service with minimal maintenance.

CM's are available in a full range of sizes (10 through 36) provides airflow performance from 500 to over 24,500 CFM, with static pressure capability up to 5-1/2". This single inlet backward inclined utility fan provides substantial benefits for pressure flow, low power consumption and low noise level, ideal for commercial and industrial applications.

The turbine performance minimizes unnecessary energy losses resulting in a system with high efficiency.

The CM and AMCA-C are available in four distinctly different construction arrangements to meet a wide range of demanding specialized exhaust or supply applications.

UL705 units have a 5-year fan housing warranty, CM-RHUL units have a 2-year fan housing warranty, and CM-HT units have a 1-year fan housing warranty. 1-year motor warranty.

| Size | CFM Range | Max SP | ||

| 10 | 3/4 HP | 499 to 1623 | 3-1/2" | 123 |

| 12 | 2 HP | 778 to 3110 | 5" | 154 |

| 14 | 3 HP | 960 to 4080 | 5" | 172 |

| 16 | 3 HP | 1192 to 4694 | 5" | 202 |

| 18 | 5 HP | 1504 to 6486 | 5" | 251 |

| 20 | 5 HP | 1864 to 7806 | 5" | 287 |

| 22 | 7-1/2 HP | 2360 to 10620 | 5" | 389 |

| 24 | 10 HP | 2960 to 13505 | 5" | 465 |

| 27 | 15 HP | 3760 to 15980 | 5" | 680 |

| 30 | 15 HP | 4608 to 18144 | 5" | 931 |

| 36 | 15 HP | 5808 to 23958 | 5" | 1228 |

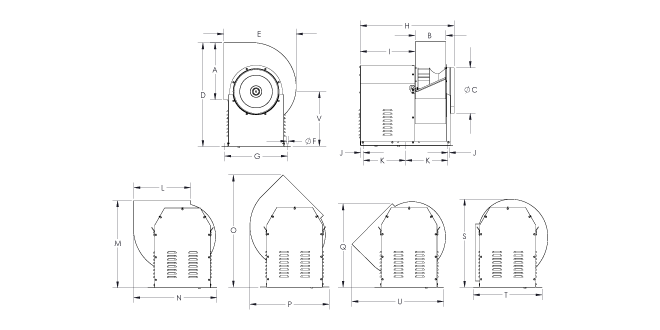

Dimensional data is displayed in inches.

| Size | A | B | C | D | E | F | G |

| 10 | 12-3/4 | 7-1/8 | 9-7/8 | 23-7/8 | 17-1/4 | 1/2 | 16-3/4 |

| 12 | 16 | 8-3/4 | 12-3/8 | 29-3/16 | 21-3/8 | 1/2 | 19-13/16 |

| 14 | 17-13/16 | 9-3/4 | 14 | 32-3/4 | 22-3/4 | 1/2 | 19-13/16 |

| 16 | 20 | 10-3/4 | 15-3/4 | 36-3/4 | 25-1/4 | 1/2 | 21-5/16 |

| 18 | 22-1/2 | 12-1/8 | 17-3/4 | 40-7/8 | 28-1/2 | 1/2 | 24-1/16 |

| 20 | 25-1/4 | 13-5/8 | 19-3/4 | 44-7/8 | 31-1/4 | 1/2 | 26-15/16 |

| 22 | 28-1/4 | 15-1/4 | 22 | 49-3/8 | 35 | 1/2 | 29-5/16 |

| 24 | 31-5/8 | 17 | 24-3/4 | 57-1/16 | 39-1/8 | 1/2 | 32-1/4 |

| 27 | 35-1/2 | 18-7/8 | 28 | 59 | 44 | 1/2 | 35-3/16 |

| 30 | 39-3/4 | 21 | 31-1/2 | 64 | 49-1/4 | 1/2 | 39-1/2 |

| 36 | 44-1/2 | 23-3/8 | 35-1/2 | 71-13/16 | 55-1/4 | 1/2 | 44-11/16 |

| Size | H | I | J | K | L | M | N |

| 10 | 25-3/8 | 15-1/2 | 2-3/16 | 9-13/16 | 12-3/4 | 21-5/8 | 20 |

| 12 | 28-3/4 | 17 | 1-5/8 | 11-13/16 | 16 | 26 | 24-1/4 |

| 14 | 30-3/4 | 17-7/8 | 2-1/2 | 11-13/16 | 18 | 28 | 25-7/8 |

| 16 | 31-5/8 | 18 | 2-1/4 | 12-5/8 | 20 | 31-1/8 | 29-1/4 |

| 18 | 37 | 21-5/8 | 1-7/8 | 15-3/4 | 22-1/2 | 34-3/8 | 32-3/4 |

| 20 | 38-3/8 | 21-5/8 | 2-11/16 | 15-3/4 | 25-1/4 | 37-1/2 | 36-1/8 |

| 22 | 40-1/8 | 21-5/8 | 1-11/16 | 17-11/16 | 28-1/4 | 41 | 40-1/8 |

| 24 | 41-7/8 | 21-5/8 | 2-3/8 | 17-11/16 | 31-5/8 | 45-7/8 | 44-5/8 |

| 27 | 50 | 27-1/4 | 1-15/16 | 21-13/16 | 35-1/2 | 55-5/8 | 50-5/8 |

| 30 | 53-3/4 | 28-3/4 | 1-15/16 | 23-5/8 | 39-3/4 | 62-3/8 | 57-1/8 |

| 36 | 54-15/16 | 27-5/16 | 1-15/16 | 24-3/16 | 44-3/4 | 70-1/2 | 64-3/8 |

| Size | O | P | Q | S | T | U | V |

| 10 | 25-7/8 | 19-3/8 | 21-5/8 | 20-3/8 | 18-7/8 | 22-7/8 | 13-1/4 |

| 12 | 32-1/2 | 23-1/8 | 24-3/4 | 24-7/8 | 21-7/8 | 27-1/2 | 15-3/4 |

| 14 | 35-5/8 | 24-5/8 | 27 | 28-1/4 | 23-1/4 | 29-3/8 | 17-11/16 |

| 16 | 39-7/8 | 27-5/8 | 29-7/8 | 31-3/8 | 26 | 32-1/4 | 19-11/16 |

| 18 | 44-1/8 | 38-1/4 | 33-3/4 | 34-3/4 | 29-1/4 | 36-7/8 | 21-5/8 |

| 20 | 48-3/8 | 34-1/4 | 37-1/8 | 38-1/8 | 32-3/8 | 40-1/2 | 23-5/8 |

| 22 | 53-1/4 | 37-3/4 | 40-3/4 | 42 | 35-3/4 | 45-3/8 | 25-9/16 |

| 24 | 59-3/4 | 42-1/8 | 45-1/2 | 47 | 39-7/8 | 50-3/4 | 30-1/4 |

| 27 | 71-1/2 | 46-1/8 | 54-7/8 | 57-1/4 | 44 | 57-1/2 | 28-3/4 |

| 30 | 80-1/8 | 51-1/4 | 62-1/2 | 63-1/4 | 49-1/4 | 61-1/4 | 30 |

| 36 | 89-3/4 | 57-1/2 | 70-5/8 | 70-5/8 | 55-1/4 | 72-3/8 | 33-1/2 |

Note: Additional accessories are available for certain products. Contact your JencoFan Representative for more information about these accessories.

Standard Accessories

| Inlet Guard | Submittal | |

| Outlet Guard | Submittal | |

| Outlet Flange | ||

| U-Flange Inlet | Submittal | |

| Discharge Damper | Submittal | |

| RIS Vibration Pads | ||

| Spring Vibration Pads | ||

| Grease Trough | Submittal | |

| Shaft Seal | Submittal | |

| Disconnect Switches | ||

| Heat Slinger | Submittal | |

| AMCA-C Assembly Kit | Submittal | |

| Ventilation Gas Detectors | Submittal | IOM |

CM

- General/Clean Air

- Contaminated Air

- Spark Resistant

- High Temperature above 200°F

CM-RHUL

- General/Clean Air

- Contaminated Air

- Spark Resistant

- Grease/Restaurant (UL 762)

- High Temperature above 200°F

CM-HT

- General/Clean Air

- Contaminated Air

- Spark Resistant

- Smoke Control (UL)

- High Temperature above 200°F